The Scientific Research Behind Galvo Scanner Modern Technology and Just How It Functions

The Scientific Research Behind Galvo Scanner Modern Technology and Just How It Functions

Blog Article

Comprehending Why You Required Galvo for Precision in Laser Applications

The integration of galvo modern technology in laser applications represents a substantial innovation in attaining accuracy and effectiveness. By making use of high-speed mirrors to route the laser beam, galvo systems not only enhance functional rate but additionally maintain the precision needed for complicated jobs such as inscription and cutting. This ability is particularly essential in industries where precision is non-negotiable. Comprehending the nuances of galvo systems-- including their advantages, essential features, and optimum applications-- can be crucial in maximizing their potential. Checking out these facets might disclose crucial understandings that can transform your approach to laser innovation.

What Is Galvo Modern Technology?

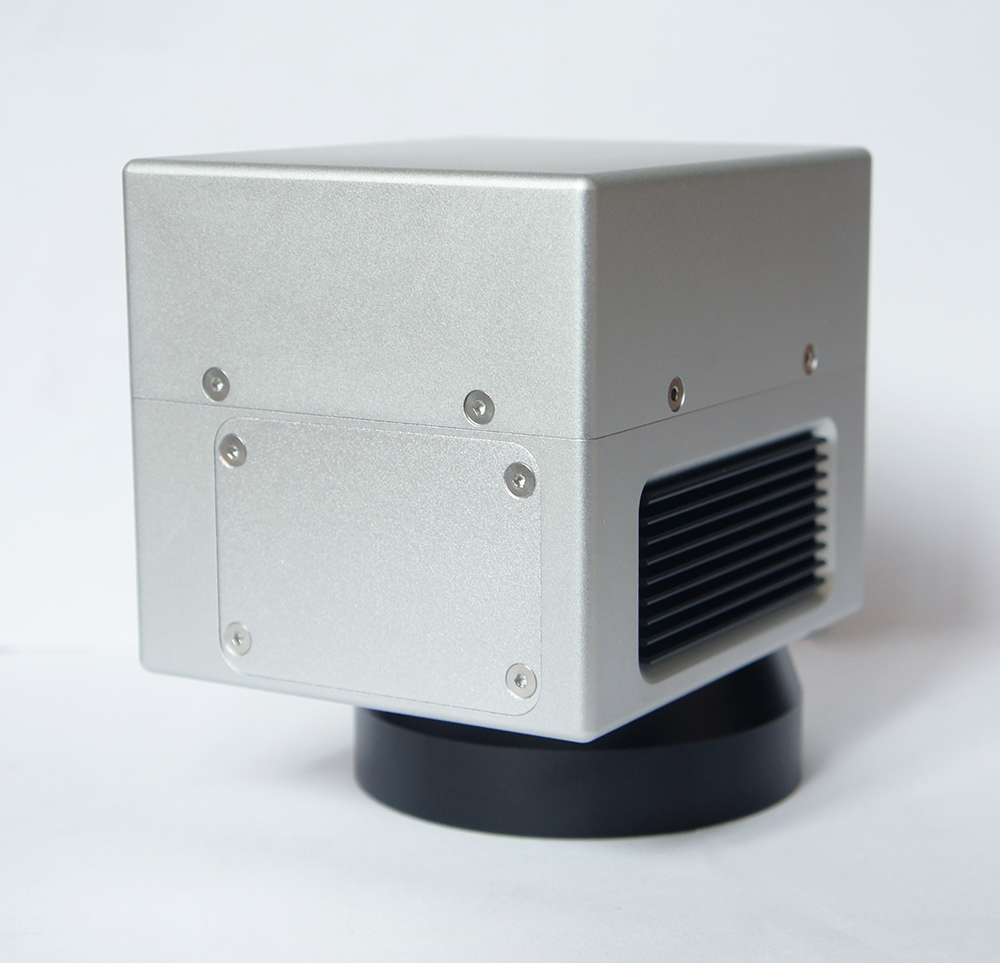

Galvo technology, brief for galvanometer technology, is a precision control system that uses mirrors placed on galvanometer motors to guide laser light beams with high accuracy. This cutting-edge approach permits specific and rapid positioning of laser light, making it an essential element in different laser applications, consisting of inscription, cutting, and noting.

In a regular galvo system, the galvanometer motors are accountable for turning the mirrors. The digital control system equates the desired laser course into electric signals, which advise the motors to move the mirrors appropriately. This makes it possible for the laser beam of light to be guided at details angles and locations with very little latency, improving the performance of the laser process.

Galvo technology is particularly helpful in applications that need high-speed procedure and detailed designs, as it lowers the mechanical movement of the laser resource. Rather, the mirrors can swiftly rearrange the beam, allowing intricate patterns and layouts to be implemented with precision. The capacity to rapidly transform the instructions of the laser light beam while maintaining accuracy is what sets galvo innovation apart, making it a foundation of contemporary laser machinery and applications.

Advantages of Galvo Solutions

Among the vital benefits of utilizing galvo systems in laser applications depends on their ability to boost functional rate and performance. Unlike typical laser systems that count on moving the entire laser head, galvo systems use high-speed mirrors to direct the laser light beam. This substantially minimizes the moment needed for positioning and enables quick handling of complicated patterns.

An additional advantage is their compact layout, which helps with assimilation right into various setups without requiring extensive adjustments. This space-saving characteristic permits higher adaptability in laser system design, suiting varied functional atmospheres.

In addition, galvo systems can take care of a vast array of materials and densities, making them flexible tools in laser processing. Generally, the benefits of galvo systems-- enhanced speed, precision, density, and versatility-- make them an indispensable choice for modern-day laser applications.

Applications in Laser Processes

Countless applications in laser procedures gain from the precision and rate offered by galvo systems. These systems are essential to industries such as engraving, cutting, and noting, where accuracy and rate directly effect efficiency and product high quality. In laser inscription, galvo mirrors allow quick and accurate activity across intricate surface areas, enabling intricate styles to be engraved onto various products without endangering detail.

Furthermore, in the medical field, galvo-driven lasers are utilized in treatments like laser surgical treatment and cells ablation, where determine precision is important for individual safety and reliable treatment. Galvo Motor. On the whole, the convenience and responsiveness of galvo systems make them indispensable in numerous laser applications, driving development and improving functional capabilities across several fields

Trick Features of Galvo Mirrors

A critical part in laser systems, galvo mirrors are made to offer fast and precise beam of light steering, enabling high-performance applications. One of the key attributes of galvo mirrors is their rate; they can attain quick angular motions, enabling fast action times crucial in applications such as laser inscription, cutting, and scanning.

An additional substantial attribute is their high precision and accuracy. Galvo mirrors can position the laser beam of light with minimal variance, which is crucial for jobs that call for precise placement and repeatability. This precision is assisted in by advanced control systems that can compensate for any kind of possible errors in real-time.

Additionally, the small style of galvo mirrors permits for assimilation into smaller sized systems without endangering efficiency. Their lightweight construction likewise adds to lowered inertia, more boosting their responsiveness throughout procedure.

Furthermore, the resilience and reliability of galvo mirrors make them ideal for continuous use in demanding settings. This strength makes sure regular performance with time, reducing downtime due to maintenance or repair services. In general, the her comment is here special functions of galvo mirrors make them vital for attaining high precision and efficiency in different laser applications.

Selecting the Right Galvo System

Choosing an ideal galvo system is important for enhancing laser performance throughout different applications. When selecting a galvo system, numerous variables must be considered to make certain compatibility with particular task demands.

One more critical variable is the kind of laser being used. Different lasers, such as CO2 or fiber lasers, have unique demands concerning wavelength and power, affecting the choice of galvo mirrors. Ensure that the selected system is made to take care of the certain wavelength and power of your laser for optimal efficiency.

Furthermore, think about the software compatibility and control options offered with the galvo system. A well-integrated software option can improve functional effectiveness and make it possible for accurate control over scanning patterns.

Lastly, examine the producer's credibility and assistance solutions. A dependable producer will certainly supply not only premium items however likewise recurring technical support, which is necessary for preserving system efficiency. By meticulously considering these elements, you can select a galvo system that satisfies click to find out more your precise laser application requirements.

Conclusion

In summary, galvo innovation plays a pivotal role in enhancing accuracy and effectiveness in laser applications. The benefits of high-speed mirror systems help with rapid and precise laser light beam direction, making them necessary for detailed jobs such as inscription, reducing, and noting. By lessening mechanical motion, galvo systems ensure cleaner edges and comprehensive styles, thus satisfying the demanding standards of numerous markets. Selecting the suitable galvo system is crucial for enhancing performance in laser procedures.

The capability to quickly transform the direction of the laser beam while preserving precision is what establishes galvo modern technology apart, making it a keystone of modern-day laser equipment and applications.

Unlike traditional laser systems that depend on relocating the whole laser head, galvo systems make use of high-speed mirrors to direct the laser beam of light.Countless applications in laser processes benefit from the accuracy and rate supplied by galvo systems (Galvo Scanner).In laser cutting applications, galvo systems enhance the capacity to his response process materials such as steel, wood, and plastics with high precision, guaranteeing clean edges and marginal kerf width. Different lasers, such as Carbon dioxide or fiber lasers, have distinctive requirements regarding wavelength and power, influencing the choice of galvo mirrors

Report this page